09

06

2023

How to Store PPGI Steel ?

1. What is Color Coated Galvanized Steel Coil

Color-coated galvanized steel coil is also called color steel coil. Color-coated steel coils are made of cold-rolled steel and galvanized steel coils as substrates, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), color coating in a continuous manner (roller coating method), baking and cooling finished product. It is made of metal coils (cold-rolled steel, hot-dip galvanized steel coil , aluminum-plated steel, high aluminum alloy steel, etc.) as the base material, and various organic coatings or plastic films are coated or laminated on the surface. Color-coated steel sheets are widely used in construction, home appliances, and transportation.

2. PPGI Steel Specification

| Substrate | GI( Galvanized steel) |

| Thickness | 0.1mm-1.5mm |

| Width | 10mm-1250mm |

| Length | Upon your requirements |

| Coatings | PE,SMP,HDP,PVDF |

| Colors | As per RAL color(custom patterns are available ) |

| Packing | Stardard Export Package |

| Coil Weight | 3-6 tons (can be customized) |

| Diameter | Φ508 mm/Φ610 mm |

| Zinc Coating | 40/275 g/m2 |

| Value-added Services | Custom sample, slitting, cutting, stamping, bending, profiling, and other |

2.1 Strong Weather Resitance

The color-coated galvanized products of Jianhui Factory use the famous AKzonobel paint, which can withstand the test of various harsh weather conditions and is not easily eroded by factors such as oxidation, corrosion and sunlight. The PE, HDP, SMP, PVDF steel paint coating on its surface can effectively resist ultraviolet rays, acid rain and corrosive gases, and keep the color-coated galvanized products bright in color and full of luster.

2.2 Good Corrosion Resistance

The galvanized layer provides excellent corrosion resistance for color-coated panels. Through the galvanizing process, the contact between the steel and the external environment is effectively isolated, the service life is extended, and the corrosion resistance is improved.

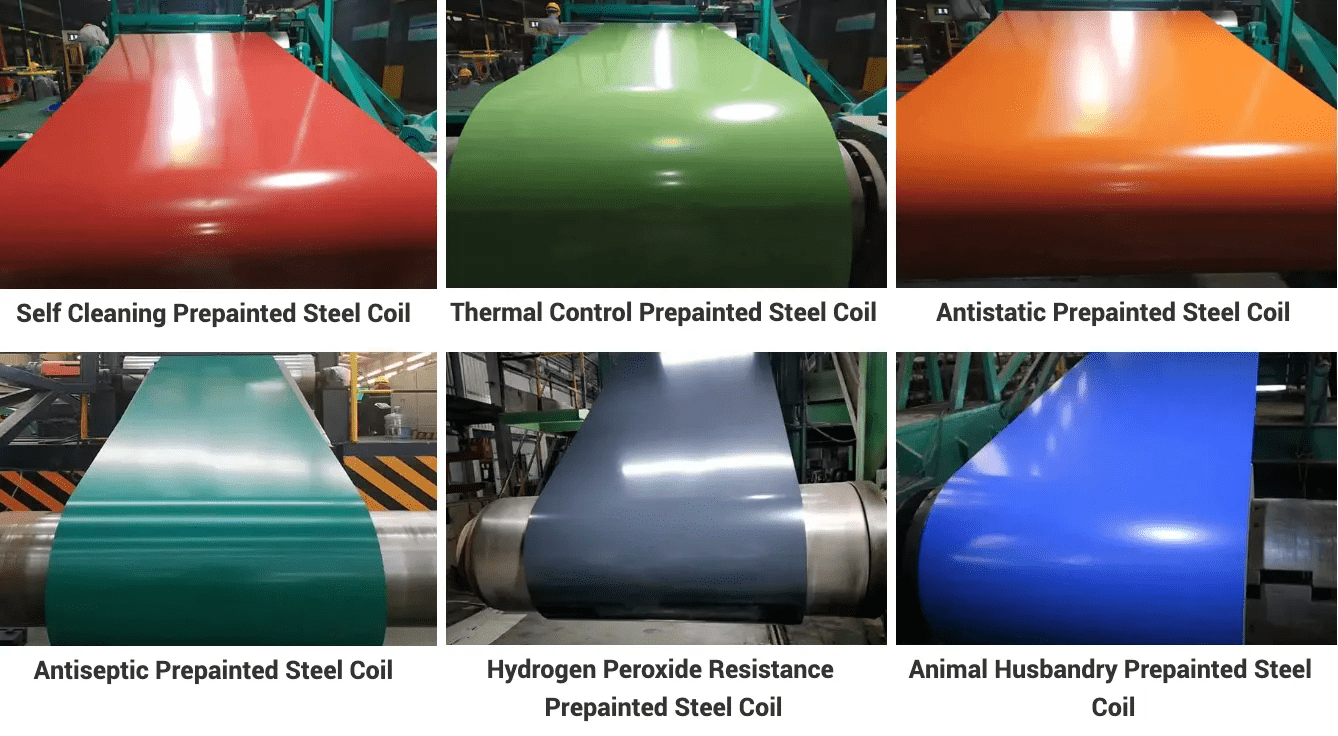

2.3 Rich Colors

Color-coated galvanized steel can be customized according to customer needs, providing a variety of color options. Bright red, blue, or steady gray, green, etc., meet the design requirements of different fields and have more application possibilities.

2.4 Convenient Construction

The color-coated galvanized sheet is light in weight, easy to cut and bend, and the construction is convenient and fast. The surface coating is smooth and uniform, suitable for various shapes and sizes, and widely used in the fields of construction and decoration.

2.5.Environmentally Friendly and Sustainable

color-coated galvanized steel coils meet environmental protection requirements. It can be recycled and reused, which is in line with the concept of sustainable development.

3.Jianhui PPGI steel coil factory has a lot of customer’s love and welcome

Color coated galvanized steel coils is a special colour coated steel , which has the characteristics of anti-corrosion, weather resistance and strong decoration. Most importantly ,Color coated galvanized steel coils storage, transportation, loading and unloading are important links that affect the quality of color coated steel coil . In order to ensure the quality of color-coated steel coils and prolong their service life, correct storage is very important. The following are some suggestion from Jianhui Steel Manufacturers for all customers to store color-coated galvanized steel coil.

3.1 Environmental conditions for steel storage

Color coated steel coils should be stored in a dry and ventilated indoor environment, avoiding storage in the open air and places with large temperature changes. Avoid direct sunlight and humid environment. To prevent corrosion and steel painting damage. In addition, avoid the erosion of various corrosive substances.

3.2 Selecting the right steel storage location

The storage location of PPGI steel plates and PPGI coils should be reasonably arranged to facilitate access and minimize unnecessary movement.

3.3 Protecting the PPGI Steel Coil Surface

The surface of the color coated steel coil is easily scratched and damaged, so special care should be taken to protect it during storage and handling. Jianhui Steel recommends using materials such as plastic film or cardboard to wrap the steel plate to prevent scratches on the steel surface.

3.4 PPGI Steel Coil Stacking Height

Avoid stacking too high, PPGI steel coil should avoid too high when stacking to prevent deformation and damage. The stacking height should not exceed 3-4 layers in general, and each layer should be isolated by using wooden boards or bedding materials.

3.5 Protect PPGI Steel Surface

The surface of PPGI steel coil is easily scratched and damaged, so special care should be taken to protect them during storage and handling. The steel plate can be wrapped with a material such as plastic film or cardboard to prevent scratches on the surface.

3.6 Moving PPGI Steel

Careful handling of PPGI steel coils is required during storage to avoid dropping them on rough ground and to prevent them from breaking.

3.7 First in First out Principle

First-in, first-out principle for steel

Implement the “first-in, first-out” system to ensure that the earliest PPGI steel coils are used first.

These are the knowledge about how to store PPGI steel coil explained to you by Jianhui PPGI steel coil factory. More importantly, these are some common suggestion for storing PPGI coil, and the specific operations need to be adjusted according to the actual situation. During storage metal, always remember to keep the steelwarehouse dry and avoid contact with harmful substances to ensure that its quality and performance are not compromised.

4.Common application scenarios of galvanized color-coated coils

4.1 Construction field

Galvanized color-coated rolls are often used for decoration and protection of building exterior walls, roofs, doors and windows. It has excellent weather resistance and corrosion resistance, while providing a variety of color options to meet architectural design needs.

4.2 Household Appliances and Electrical Appliances:

Galvanized color-coated rolls are widely used in the manufacture of household appliances, such as refrigerators, washing machines and air conditioners. It not only has a beautiful appearance, but also has good corrosion resistance and prolongs the service life of the product.

Automobile industry:

In the field of automobile manufacturing, galvanized color-coated rolls are widely used in the manufacture of body panels and body components. Its anti-corrosion properties and weather resistance can maintain the appearance and function of the vehicle in harsh environments.

Containers and packaging:

Galvanized color-coated rolls can be used to manufacture various containers and packaging materials, such as food cans and cosmetic packaging. It has excellent anti-rust and anti-corrosion properties, protecting the internal items from the external environment.

4.3 Transportation

Galvanized color-coated rolls are widely used in the field of transportation, such as the manufacture of vehicle shells and ship exterior components. Its weather resistance and corrosion resistance guarantee the service life of the vehicle under harsh conditions.

In addition to the above application scenarios, galvanized color-coated rolls can also be used in many fields such as furniture manufacturing, metal products and decoration engineering. Its excellent properties and variety of color options make it a popular material used in a wide range of industries.

5.What are the tests for galvanized color-coated steel coils?

5.1 Thickness measurement of color-coated galvanized steel coils:

Use a professional thickness gauge to measure the thickness of galvanized color-coated steel coils. Ensure that the thickness of the steel coil meets the specified standards to ensure product quality.

5.2 Film thickness measurement of color-coated galvanized steel coil

measure the thickness of color coating with a film thickness meter to ensure the uniformity and compliance of color coating. This helps to ensure that the prepainted steel coil is not easily peeled or damaged during use.

5.3 Prepainted galvanized surface quality inspection

Use visual inspection or professional surface quality inspection equipment to inspect the surface of prepainted steel coils. Check for surface defects such as scratches, spots, bubbles, pockmarks, etc. to ensure that the product looks good.

5.4 Corrosion resistance test of color-coated galvanized steel coils

use methods such as salt spray test to test the corrosion resistance of color-coated steel coils. This helps to evaluate the corrosion resistance of steel coils in harsh environments to ensure their long-term stability.

5.5 Color inspection of prepainted galvanized steel coils

The color of prepainted steel coils is inspected by colorimeter or visual inspection. Ensure color consistency and meet customer requirements.

5.6. Color-coated galvanized strength test

use tensile testing machine and other equipment to test the strength of the color-coated steel coil to ensure that it meets the strength requirements and can withstand the corresponding load.

The above are some common methods and steps for testing galvanized color-coated steel coils. Through comprehensive testing, product quality can be ensured to meet customer needs and standard requirements.

6.In Conclusion

Jianhui Steel factory is a leading global steel company committed to providing high quality steel products and steel services. Since its establishment, Jianhui has adhered to the core values of innovation, quality and customer first, and has continuously promoted the development of the industry and social progress.

Jianhui Steel Factory is always customer-centric and is committed to providing all customers with high-quality steel products. We have established long-term and stable cooperative relations with world-renowned enterprises. The company strictly follows international quality standards and continues to invest in steel production to maintain the competitiveness of our products and services.