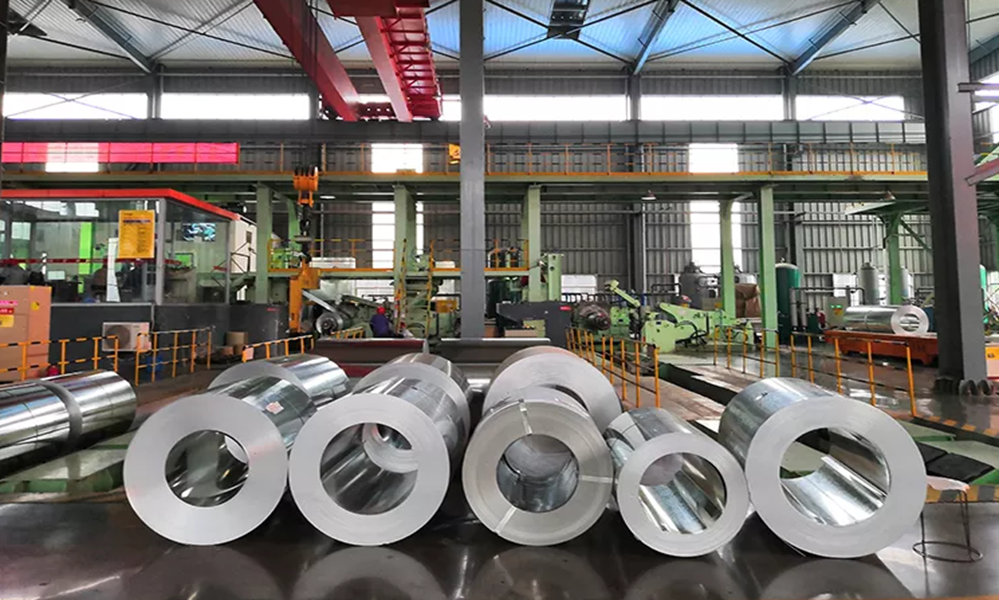

Aluminum steel coil production process and production precautions

Aluminum steel coil production process

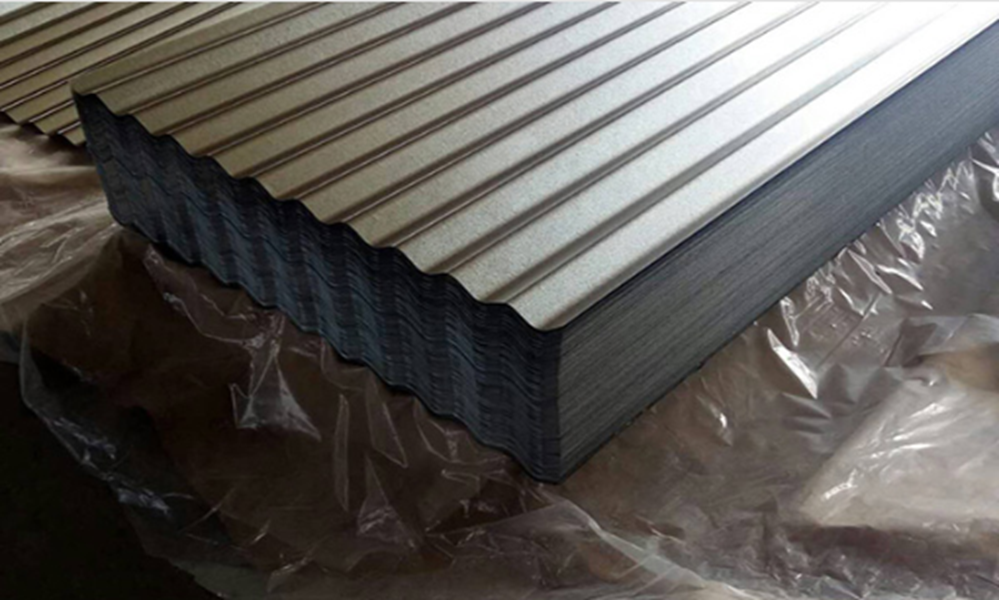

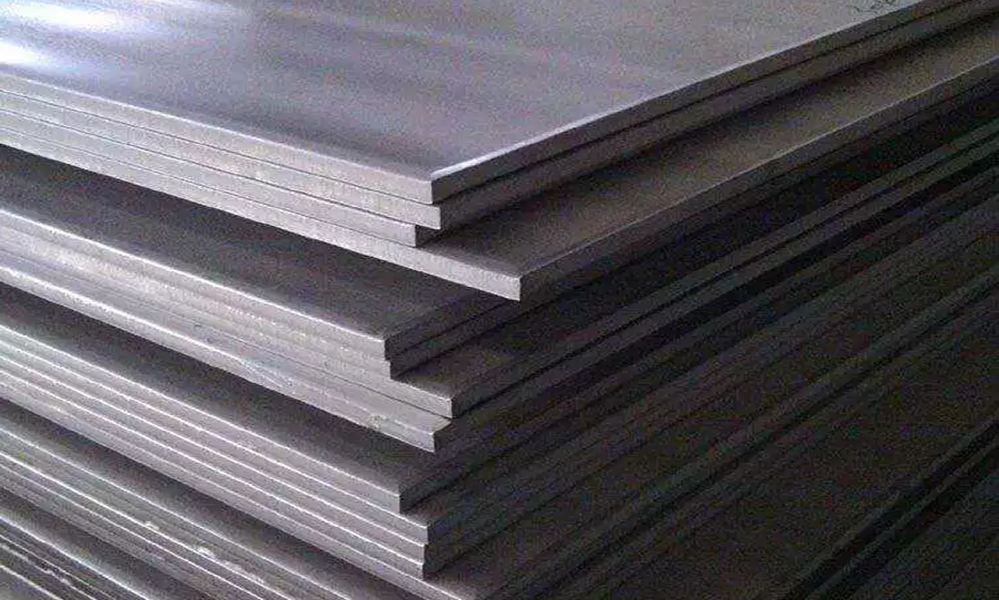

The primary aluminum ingots are put into the melting furnace, ignited and melted with natural gas, the slag is stripped and the waste is removed, equipped with aluminum alloy, the furnace is guided to the holding furnace, the aluminum water is poured, and it is hand-carved according to the engineering drawings, edge pressing, ribs, welding, polishing, painting, testing , Paste protective film, packaging air cushion cc film, packaging, loading arrangement...