22

2020

China Top PPGI Steel Coils Manufacturer

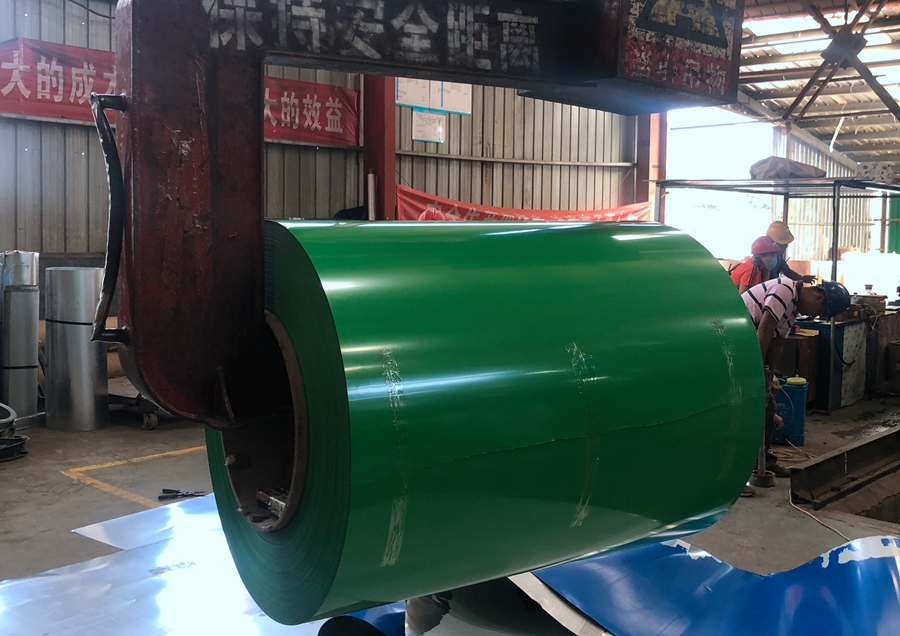

ppgi steel coil is one of the commonly used sheets in the construction industry. It is usually made of cold-rolled sheet, hot-dip galvanized sheet, aluminized sheet and other sheets as the base material and coated with various organic coatings on the surface, which can be directly processed into products. Used in industrial plants, gymnasiums, warehouses, airports and other places. The structure of ppgi steel coil can be divided into: topcoat, primer, coating, substrate, backcoat from top to bottom.

When the topcoat of ppgi steel coil is of a specified thickness, a shielding coating can be formed, which can effectively shield the sunlight and prevent the damage of the coating caused by ultraviolet rays. At the same time, it can also reduce water permeability and oxygen permeability. The primer of ppgi steel coil contains anti-corrosion pigments, which can improve the corrosiveness and help to strengthen the adhesion to the substrate. Even if the paint film is permeable to water, it is not easy to desorb the paint. The coating of ppgi steel coil has the greatest influence on the service life of the product. The thicker the coating, the better the corrosion resistance. Generally, the coating is galvanized or galvanized. The strength of the substrate of ppgi steel coil determines the mechanical properties of ppgi steel coil. The function of ppgi steel coil back paint is to prevent the steel plate from corroding from the inside.

Generally speaking, the effective means to prevent the corrosion failure of ppgi steel coil is to increase the thickness of the coating and use a weather-resistant and corrosion-resistant coating. So what are the factors that affect the use of ppgi steel?

The first is the type of coating of ppgi steel coil, which we will discuss in detail in future articles. The second is the thickness of the ppgi steel coil paint film. Generally speaking, the thicker the coating thickness, the better the corrosion resistance of the substrate. This is because there are many pinholes in the coating of ppgi steel coil. The size of the pinholes will cause the corrosion medium to penetrate into the substrate and cause corrosion. The thicker the coating of ppgi steel coil, the fewer pinholes there are in the coating. According to the salt spray test results under different coating thicknesses, the anticorrosion effect of ppgi steel coil will be relatively stable when the coating thickness is above 20 μm.

The quality of the coating will also affect the use of ppgi steel coil. If ppgi steel coil is directly color-coated with cold-rolled substrate without coating, its corrosion rate will be faster, because the corrosion products of iron are loose and easy to absorb moisture, which cannot form secondary protection for ppgi steel coil. If a relatively thick galvanized or galvanized substrate is used, the corrosion resistance of the product will be improved. The ppgi steel coil produced by Henan Jianhui Steel Co.,Ltd is guaranteed to be galvanized or galvanized substrate, with a coating thickness of more than 20μm, to make high-quality ppgi steel coil for customers.