31

07

2023

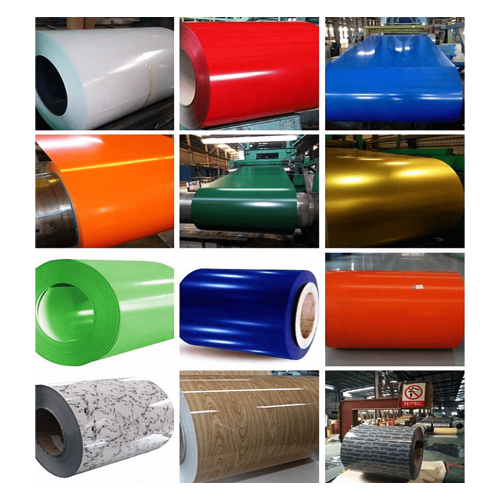

50 Most Frequently Asked Questions on PPGI

Are you ordering PPGI from China? Do you have some questions about PPGI steel coil but don’t know where to start looking for answers?

In this article, we have compiled 50 of the most frequently asked questions about ppgi coil to help you navigate the world of PPGI steel.

Part 1. Basics of PPGI 10 tips

What is PPGI Steel Coil ?

PPGI steel is a kind of pre-painted galvanized steel , the full name of PPGI is “Pre-Painted Galvanized Iron”, also known as a pre-painted zinc-coloured steel sheet. It is a kind of special steel sheet by coating one or more layers of organic coating on the surface of cold rolled substrate, and then applying one or more layers of coloured coating on top of it.PPGI steel sheet has the features of good weather resistance, various colours, easy construction, etc., and it is widely used in the fields of construction, household appliances and transportation.

What is PPGI Steel used for?

PPGI steels are widely used for a variety of applications, including construction, home appliances, transport, and industrial equipment. The following are the main applications of PPGI steel sheets:

Construction

PPGI steels are commonly used as building materials for exterior walls and roofs and offer a wide range of color and appearance options due to its excellent weather resistance and decorative properties.

Household appliances

PPGI steel plate can be used for the shell of household appliances, such as refrigerators, washing machines, microwave ovens, etc., so that the appliances have a beautiful appearance and provide a variety of colour options.

Transportation applications

PPGI steel sheets are commonly used in the exterior decoration and body panels of cars, trains, motorbikes, and other transportation vehicles to increase the aesthetics and durability of the vehicles.

Industrial equipment used

PPGI steel plate is also used in the manufacture of some industrial equipment and machinery to provide external protection and aesthetic effect.

Overall, PPGI steel sheets are used in a wide variety of fields to provide aesthetics and protection for products and buildings due to their appearance versatility, and weather resistance.

What is PPGI Steel made of?

Steel Substrate

The substrate of the PPGI steel sheet is a cold rolled galvanized steel sheet which has good strength and corrosion resistance.

Galvanized

A layer of zinc is coated on the surface of the cold rolled steel sheet, which is called galvanised. Galvanising prevents corrosion and increases the life of the steel sheet.

Organic Coating

Galvanised steel sheets are first coated with one or more organic coatings. These organic coatings are usually made of materials such as polyester, polyamide, polyethylene or polypropylene and are used to increase the weathering and corrosion resistance of PPGI steel sheets.

Colored coatings

One or more layers of colored coatings are applied on top of the organic coatings to give the desired color and appearance to the PPGI steel sheet.

Through the combination of these layers, PPGI steel sheets can provide a wide range of color and appearance options with good weather resistance and decorative properties and are widely used in construction, home appliances, transportation, and other fields.

What is the paint used for galvanized coils?

PE

Polyethylene Coating (Polyethylene Coating), a common organic coating material for PPGI steel sheets with good weather resistance and decorative properties, widely used in home appliances, furniture and other interior decoration areas.

PVDF

Polyvinylidene Fluoride Coating, a high-performance organic coating material for PPGI steel sheets with excellent weatherability and corrosion resistance, suitable for buildings and equipment used in harsh environmental conditions.

HDP

High Durability Polyester Coating, an organic coating material for PPGI steel sheets with high weather resistance, suitable for long term colour and appearance stability in harsh climatic conditions.

PVC

Polyvinyl Chloride Coating (Polyvinyl Chloride Coating), a commonly used organic coating material for PPGI steel sheets, suitable for billboards, signs and decorations and other occasions that require printing patterns.

The above are some common types of PPGI steel coating, each coating material has different characteristics and uses, according to the specific application needs, choose the right type of coating can achieve better results.

What are the Different Types of PPGI?

Polyester PPGI

This type of PPGI steel sheet uses polyester resin as the organic coating material and is usually used for general construction and household appliances. Polyester PPGI steel sheets have better weathering and corrosion resistance.

Polyamide PPGI

PPGI steel sheets using polyamide resin as the organic coating material have higher weathering and corrosion resistance and are suitable for buildings and equipment used in harsh environmental conditions.

Polyethylene PPGI

This type of PPGI steel sheet uses polyethylene resin as the organic coating material, and is mainly used for appliances, furniture, and other interior decorative purposes.

Highly Weather Resistant PPGI

This type of PPGI steel sheet uses a variety of highly weather- resistant organic coatings that allow it to maintain color and appearance stability over time in extreme weather conditions.

Printed PPGI

This type of PPGI steel sheet has a printable surface that can be used in applications where printed graphics are required, such as billboards, signs, and decorations.

Anti-fingerprint PPGI

This type of PPGI steel plate has a special coating that reduces the adhesion of fingerprints and stains and keeps the surface clean.

Above are some different types of PPGI steel sheets, each type has different characteristics and uses, and choosing the right PPGI steel sheet according to specific needs can achieve better results.

What is the difference between PPGI and PPGL?

PPGI (Pre-Painted Galvanised Iron) Steel

The base material for PPGI steel sheets is cold-rolled galvanized steel, which has good strength and corrosion resistance.

PPGI steel sheets are pre-coated with an organic coating (usually polyester, polyamide, polyethylene, etc.) and then colored coats are applied to them.

PPGI steel sheets are commonly used in construction, home appliances, and transportation to provide aesthetics and weather resistance to products.

PPGL (Pre-Painted Galvalume) Steel

The base material for PPGL steel sheets is aluminum-zinc plated steel (Galvalume steel sheet), which is made up of an alloy coating of aluminum, zinc and silicon for excellent corrosion resistance.

PPGL steel sheets are also pre-coated using an organic coating, on which a colored coating is then applied.

PPGL steel sheets have better corrosion resistance than PPGI steel sheets and are suitable for use in harsh environmental conditions such as marine environments or high-humidity areas.

Overall, PPGI and PPGL are both pre-coated colored steel sheets, but the difference is in the substrate material; PPGI uses cold rolled galvanized steel as the substrate, whereas PPGL uses aluminium-zinc plated steel (Galvalume steel) as the substrate and PPGL has the advantage of better corrosion resistance. Choosing the right type for your specific application will achieve better results.

What is the typical width of PPGI?

Typical widths of PPGI steel plates can vary depending on the manufacturer and customer requirements. Generally speaking, the typical width of PPGI steel plates usually ranges from 600 mm to 1250 mm.Jianyehui Steel can make special width , for example 750mm/800mm/900mm/914mm/1219mm/1220mm/1250mm

What is the inner and outer diameter of the PPGI Coil?

The size of the inner and outer diameters of PPGI coils usually depends on the manufacturer and the specification of the coil. In general, the inner diameter of PPGI coils is usually between 508 mm and 610 mm, while the outer diameter is usually between 1500 mm and 2000 mm.

How long is the PPGI Steel Coil lifespan?

The service life of PPGI steel sheets depends on a number of factors, including environmental conditions, coating quality, sheet thickness and proper maintenance. In general, PPGI steel sheets can have a service life of between 15 and 30 years.

High-quality PPGI steel sheets, especially models with high weather and corrosion resistance, can last longer in harsh climatic conditions. Also, proper installation and maintenance can extend the life of PPGI steel sheets.

However, it is important to note that the service life can vary depending on environmental factors, pollution levels, sun and rain. Regular inspection, cleaning and maintenance are essential to ensure the longevity of PPGI steel sheets.

Overall, the selection of quality PPGI steel sheets, proper construction and proper maintenance will ensure their effective use within their expected life span.

How should I store PPGI?

DRY STORAGE

PPGI steel sheets should be stored in a dry, ventilated area to avoid prolonged exposure to wet conditions. Wet conditions may cause surface corrosion or coating damage to the steel sheet.

Protection from moisture

When storing PPGI steel sheets, avoid contact with water, rain or other liquids. Steel plates should be kept off the ground to protect them from moisture.

AVOID DIRECT SUNLIGHT

PPGI steel plates should be stored so as to avoid prolonged exposure to direct sunlight, especially in hot climates. Prolonged exposure to sunlight may affect the quality and color of the coating.

Stacking specification

When stacking PPGI steel plates, keep the plates neat and smooth, and avoid stacking too high, which may lead to deformation or damage.

Regular Inspection

Regularly inspect the stored PPGI steel plates to ensure that they are in good condition. If any corrosion, coating damage or other problems are found, take timely measures to repair or replace them.

Proper storage can protect the quality and appearance of PPGI steel plates and extend their service life. Therefore, it is important to observe the above precautions when storing PPGI steel plates to ensure that the quality and performance of the plates are not compromised.

Part 2. How to Choose PPGI Steel Coils 10 Tips

Quality of steel plate

Choose a well-known brand or a supplier with a good reputation to ensure that the quality of PPGI steel coils meets the standard.

Coating type

Choose the right type of coating (PE, PVDF, HDP, PVC, etc.) according to project requirements and environmental conditions.

Size

Choose the right size of PPGI steel coils according to project requirements to avoid waste and additional processing costs.

Corrosion resistance

Pay attention to the corrosion resistance of PPGI coils, especially for applications exposed to wet or corrosive environments.

Weathering

Select PPGI coils with sufficient weathering resistance to ensure long-term stability in accordance with the climatic conditions of the project site.

Colour and Appearance

Select the colour and appearance of the PPGI coils to suit the design and decorative needs of the project.

Price and budget

Consider both quality and price to ensure that the PPGI steel coils are within budget and avoid compromising quality at the cost.

Supplier service

Choose a reliable supplier who provides timely delivery, after-sales service and technical support.

Sample test

Before purchasing in large quantities, you can ask the supplier to provide samples for testing to confirm the quality and performance.

Evaluation

Consult other customers or industry experts for more comprehensive information about suppliers and PPGI steel coils.

The above suggestions will help you make an informed decision when selecting PPGI Steel Coil, ensuring a smooth project and quality results.

Part 3. Quality Control of PPGI 11 tips

Raw material source

Where does your PPGI steel coil raw material come from?

China

Quality of raw materials

Strict quality inspection is carried out on raw materials such as coatings and galvanized steel sheets to ensure that they meet the standard requirements.

Production Process

Which production process do you use to manufacture PPGI coils? Whether to adopt advanced technology and equipment?

Jianyehui Steel can guarantee quality because of our most advanced production line.

Coating Quality

How do you ensure that the coating is of uniform quality and adheres well?

Paint coating Testing

Coating adhesion

The adhesion of the coating is tested by appropriate test methods to ensure that the coating is firm and not easy to peel off.

Galvanized Coating Thickness

Measure the thickness of the galvanized coating to ensure it meets product specifications and performance requirements.

Surface inspection

Do you perform a visual inspection of the surface of your PPGI coils to ensure there are no defects or damage?

Of Course

Corrosion Resistance

Have you tested for corrosion resistance? Can PPGI steel coils effectively resist corrosion in harsh environments?

Of course

Dimensional Accuracy

How do you ensure that the dimensional accuracy of PPGI steel coils meets the specified requirements? Have dimensions been measured?

Width Test and Thickness Test

Physical properties

Have you done physical property tests on PPGI steel coils

such as bending properties, tensile properties, etc.?

Yes , We have Thickness Test, Width Test, Zinc Coating Test , Paint Coating Test, Gloss Measure Test, Salt Spray Test, Impact Test, Exposure Test, bending properties, tensile properties

Packaging and Shipping

How do you pack and ship PPGI steel coils to ensure they are not damaged during transit?

Packaging inspection: Check whether the packaging of the product is qualified to prevent damage during transportation.

Part 4. Purchasing PPGI 4 Tips

Where can I buy PPGI?

PPGI can be purchased from steel manufacturers or from online suppliers.

What factors should be considered when purchasing PPGI?

How to compare the price of PPGI from different suppliers?

Compare unit prices and shipping costs from different suppliers.

How to evaluate the PPGI quality of different suppliers?

Select PPGI samples from reputable suppliers and conduct quality control testing.

How to choose a reputable PPGI supplier?

Choose a reputable supplier with good reviews and a history of delivering quality products.

Part 5 : PPGI Galvanised Coil 9 Testing Ways

Thickness Test

Width Test

Zinc Coating Test

Paint Coating Test

Gloss Measure Test

Salt Spray Test

Impact Test

Exposure Test

Part 6: PPGI Galvanised Coil 6 Testing Tools

Hardness Tester

Measuring Tape

Zinc Layer Thickness Gauge

Microcomputer Control Electronic Universal Testing Machine

Salt Spray Test Chamber

Color Paint Coating Bending Machine

Contact us Now

Jiayehui Steel Factory has grown to become the largest manufacturer of PPGI Steel in China. An ISO 9001-certified company, Jianyehui Steel produces a broad and comprehensive range of building materials

products and offers industrial services from its facilities all over China. We are the largest manufacturer of PPGI Steel Coil .