22

2020

The production process and production process of colour coated sheet

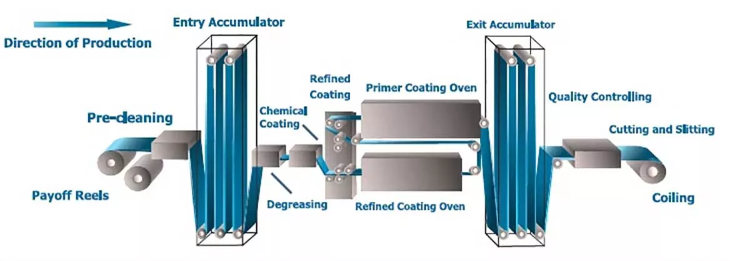

The production process of colour coated sheet: on the continuous unit, cold-rolled strip steel and galvanized strip steel (electro-galvanized and hot-dip galvanized) are used as substrates, and after surface pretreatment (degreasing and chemical treatment), they are coated by roller coating method. One or more layers of liquid paint, after baking and cooling, the resulting sheet is the coated steel sheet. Since the coating can have various colors, it is customary to call the coated steel sheet colour coated sheet. And because the coating is carried out before the steel plate is formed, it is also called pre-coated steel plate abroad.

The technological process is as follows: colour coated sheet is based on cold-rolled steel sheet and galvanized steel sheet, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), coating with continuous method (roller coating method), after baking and cooled products.

The main production process of the common two-coating and two-bake continuous color coating unit process flow is: uncoiling → pretreatment → coating → baking → post-processing → coiling. Uses of colour coated sheet: construction industry (outdoor) workshops, agricultural warehouses, residential prefabricated components, corrugated roofs, household appliances, etc.

The colour coated sheet adopts the two-coating and two-baking production process. In order to ensure the coating quality of color-coated products, it is necessary to carry out pre-treatment work such as degreasing, dust removal, and rust removal on the surface of the substrate before coating. This is the first step to ensure the coating process and the quality of the color coated sheet products. basic work. The purpose of the treatment is to carry out chemical coating treatment on the clean substrate surface after removing the anti-rust oil, rust spots, dust, etc. attached to the surface of the substrate to form a network chemical conversion film with Cr6+ and Cr3+ as the basic skeleton. Increase the adhesion between the substrate and the coating, improve the corrosion resistance of the substrate and the durability of the coating. The quality of the work determines the quality of the coating, and directly affects the physical indicators such as the flexibility and impact resistance of the coating. Determines the coating adhesion of colour coated sheet products. The purpose of initial coating, finishing coating and curing is to coat the coating on the substrate surface and use heating to volatilize the organic solvent of the coating, so that the organic coating and the substrate are closely combined.

The product quality of colour coated sheet is not only determined by the basic properties of the substrate and coating, but also depends on the production process and operation control technology. Operation control technology has a great influence on the physical properties and surface quality of colour coated sheet products. From the production process analysis, the key points of production control technology should include cleaning treatment, chemical coating treatment, coating (including initial coating, fine coating), curing 4 links