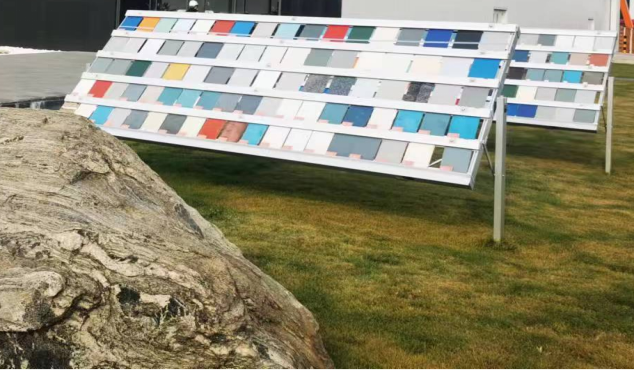

| Standard: | JIS G3312 | Top Coating: | 10-15um |

| Back Coating: | 5-7um | Zinc: | 40g/m2 |

| Color: | RAl Color/as Required | Coil Weight: | 3-12MT |

| Coil ID: | 508mm/610mm | Gloss: | 60-80 Degree |

| Top Paint: | Polyester | Free Sample: | OK |

They are made of Cold Rolled Steel, Which can be widely used in Highway Guard Rails, Walls, Garages, Big Truck Boxes, and all kinds of buildings.

Application for Galvanized Corrugated Steel Sheets: Automotive, machinery, appliance, printing, construction, building materials, bicycles, and other industries, and the production of organic coated steel is also the best selection.

1. We are pleased to offer better prices and product recommendations. Including inventory and application.

2. We are pleased with any time to provide the latest market price information.

3. Welcome to visit our factory. We guarantee you a pleasant time in China.

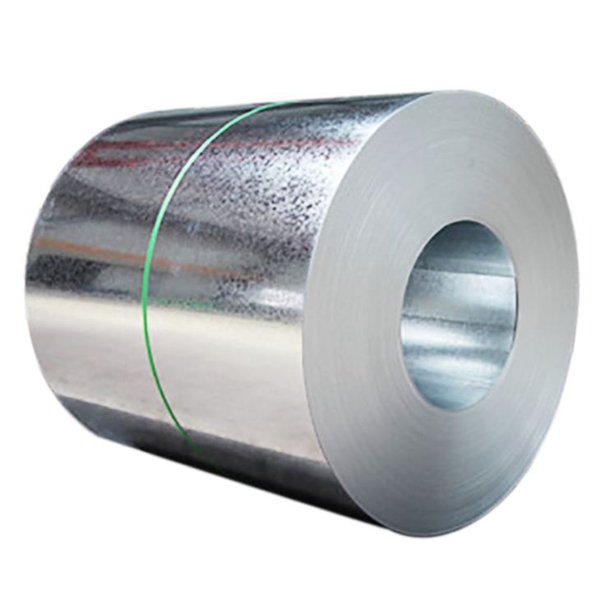

Type-01: PPGI For Corrugated Roofing Sheets Contains Hot-Dipped Galvanized Steel Coil

| Substrate | Hot Dipped Galvanized Steel Coil |

| Steel Grade | DX51D+Z~DX56D+Z, DC51D, Q195, Q235, Q235A, ST02Z, CS-B, etc |

| Standard | JIS G3302-2007, GB/T2518-2008, ST02Z, DIN EN 10327, ASTM A653 |

| Thickness | 0.14mm~1.0mm |

| Width | 600mm~1250mm |

| Zinc Coating | Z40~Z60 / Z80~Z100 / Z120~Z150 / Z275 |

| Spangle | Regular spangle, minimum spangle |

| Edge | Mill edge, cut edge |

| Surface Treatment | Chromated, Oiled, Anti-finger print (N) |

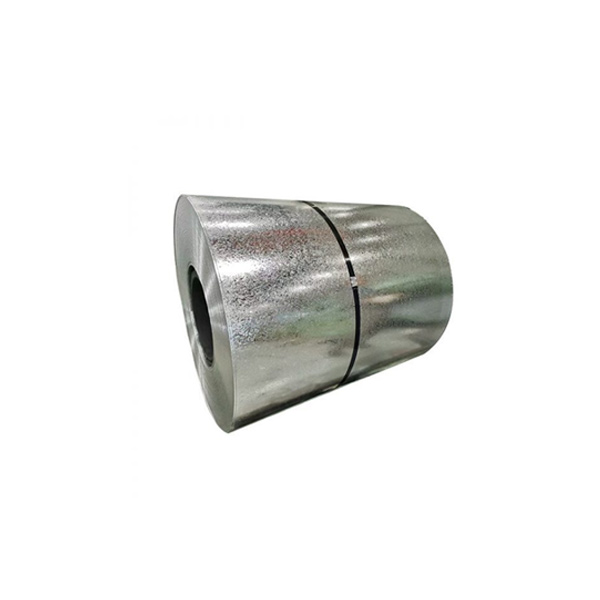

2. Galvanized Corrugated Steel Coil

| Substrate | Hot-Dipped Galvalume Steel Coil |

| Thickness | 0.14mm~2.0mm |

| Width | 600mm~1250mm |

| Spangle | Regular, Zero |

| Treatment | Skin-passed, Chromated, AFP, Oiled |

| Quality | CQ, DQ, HSLA |

Processes Of Cold Rolled Coil

Cold rolled production line is running in the form of 4 convertible rollers in a single framework, The material: Lower Carbon steel (CQ, DQ, DDQ), Lower Carbon high tensile steel (Q195, Q235, Q345), SHLA steel, deep drawing steel and if steel. Cover thickness: 0.23~1.50mm, width: 600~1250mm.

PPGI for Corrugated Roofing.

3:Processes Of Galvanized Corrugated Steel Sheets

Hot Dipped Galvanized Steel is widely used in auto, household electrical appliances, IT, advanced building materials industries, etc. The process of producing hot dipped galvanized steel is: Cold Rolled Full Hard – Payoff Reels – Degreasing – Annealing – Zinc Coating – Tension Leveling – Straightedge Forming – Chromeate or Oil.

| Characteristics Of The Continuous Galvanizing Line |

| Adopt roll-painting-chromate technology, ensuring the Cr Free and environmentally-friendly process. |

| A high-level automatic control system ensures efficiency and product quality. |

| The product is able to be well shaped after tension leveling and straight forming. |

| GI production line equipped with oiled and anti-fingerprint facilities can reach customers’ requirements. |

| zinc coating control system and technology imported from France guarantee the uniformity of zinc coating. |

| The USS method applied in galvanizing technology ensures the high quality of adhesion and surface treatment. |