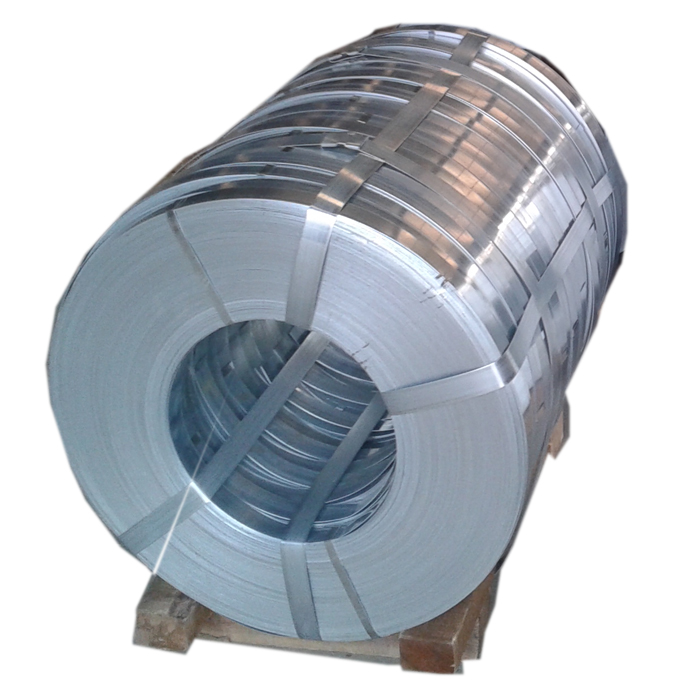

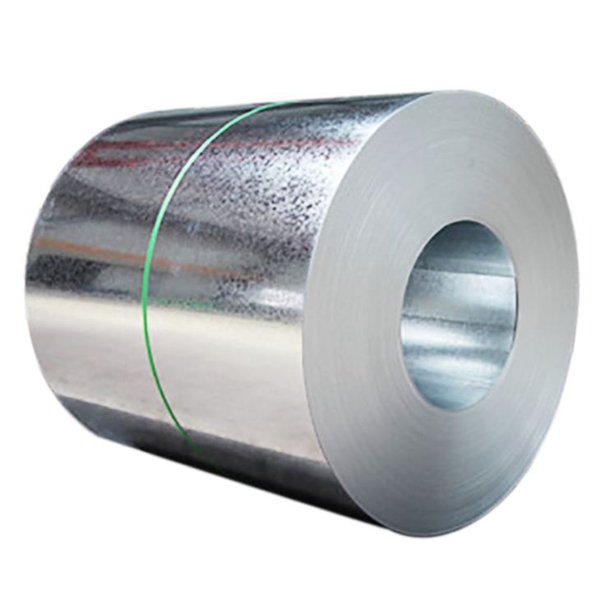

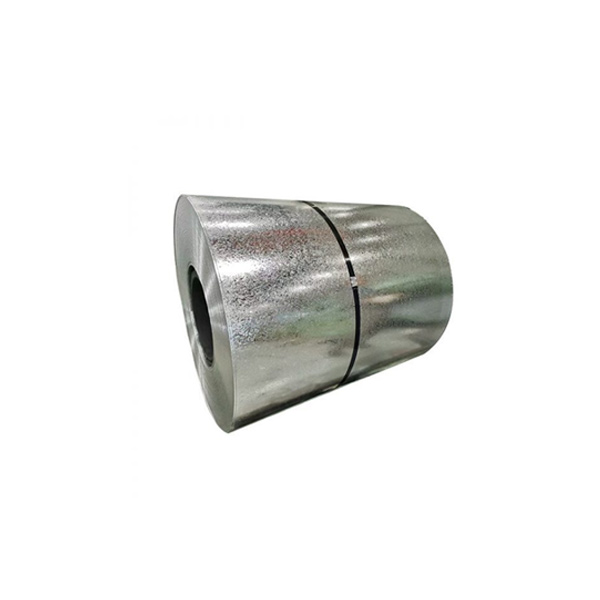

Galvanized Steel Strip

1. What is galvanized Steel Strip?

The galvanized steel strip is a type of steel that has been coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, involves immersing the steel strip in a bath of molten zinc and then allowing it to cool and solidify. The resulting coating of zinc provides a barrier against moisture, air, and other environmental factors that can lead to rust and corrosion. The Galvanized steel strip is commonly used in a variety of applications such as roofing, fencing, and automotive manufacturing.

2. galvanized Steel Strip Specification

Name: |

Galvanized Steel Strip |

Standard: |

AISI, ASTM, GB, JIS |

Material: |

DX51D,SGCC , S250gd-S550GD, G550, A653, Q235, Q215, Q195… |

Thickness: |

0.1-3.0 mm |

Width: |

10-600 mm |

Tolerance: |

“+/-0.02mm |

Zinc coating: |

60-275g/m2 |

Surface treatment: |

unoil, dry, chromate passivated, non-chromate passivated |

Spangle: |

regular spangle, minimal spangle, zero spangle, big spangle |

Coil ID: |

508-610MM |

Coil Weight: |

3-5 TON |

Technique: |

Hot rolled, cold rolled |

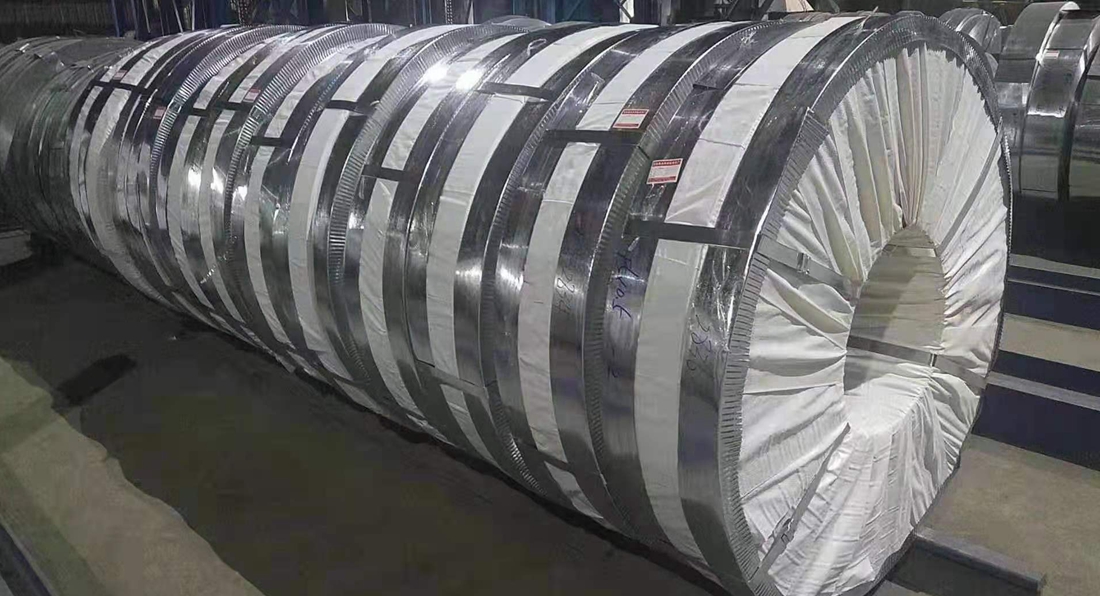

Package: |

Standard seaworthy export packing:3 layers of packing, inside are kraft paper, water plastic film is in the middle, and outside GI steel sheet to be covered by steel strips with a lock, with inner coil sleeve. |

Certification: |

ISO 9001-2008, SGS, CE, BV |

MOQ: |

5 TONS (in one 20ft FCL) |

Delivery: |

15-20 days |

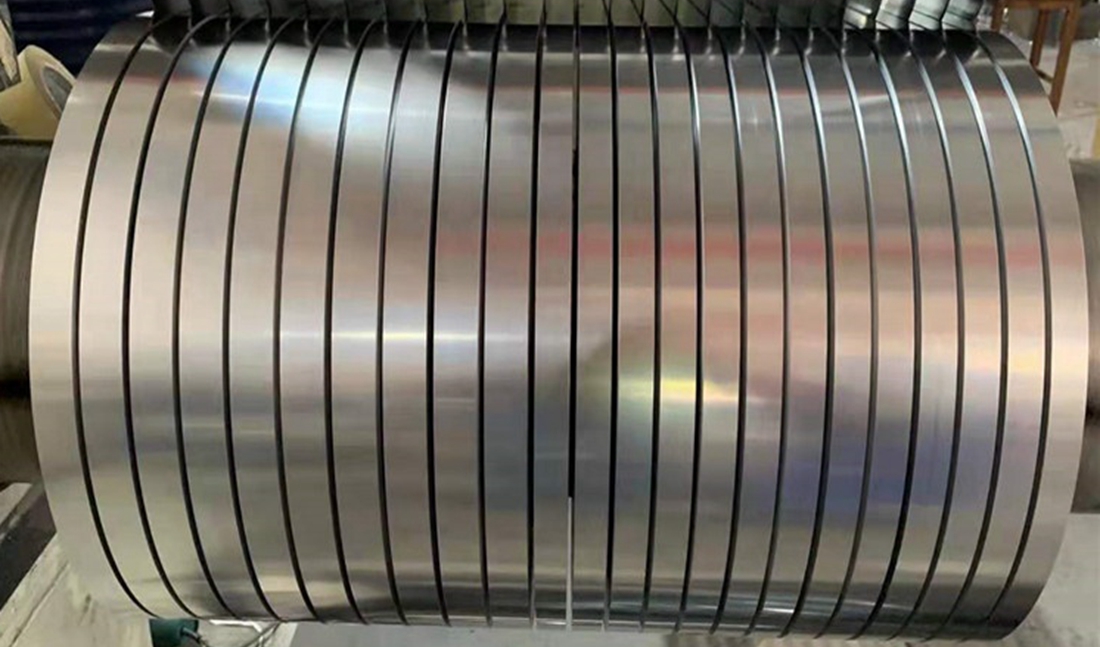

3. Tangent of Galvanized Galvalume Steel Strip

Coil tangents are used to produce smaller coils of specific widths or weights. The main loop will be threaded into the tangent and from there the desired width of the loop will be formed. The slit coil produced (sometimes called multi-coil or strip coil) is then rewound. Can be equipped with sash, sash ferrous and non-ferrous metals, as well as high-grade and ultra-high-strength steel and aluminum.

4. Application of Galvanized Galvalume Steel Strip:

Mainly used for signs, billboards, building exterior wall decoration, sheet metal processing,

High-rise building and factory wall finishes, kitchen sinks, packaging, plumbing, and Celling

Lamp, fan blade, electronics, chemical equipment, deep drawn hollow parts,

Construction, plate, welding parts, heat exchanger, decoration, electrical industrial shell

Electrical appliances.

5. The packing details

Standard seaworthy packing;

5 steel eye bands and 4 circumferential bands, inner and outer edges with steel metal groove rings, steel plate and waterproof paper wall protection plate, circumferential steel metal and waterproof paper.